Ink

High hardness antistatic ink

With the rapid development of panel technologies, the flat panel display technologies must be improved and integrated with other functions, therefore, the In-Cell/On-Cell display modules with IPS technologies which improve the wide view-angle color difference and integrated functions have come along.

The IPS LCD emphasizes a wide viewing angle, the electrodes are arranged side by side so that it can be easily interfered with by external noises. Therefore, a layer of anti-static coating as a noise barrier (Shielding layer) is needed on the rear side of the filter.

In view of this, Thunder Innovation itself has developed a conductive polymer surface modification (functionalization) with organic-inorganic nanomaterials mixing technology. It has made the inorganic nanoparticles dispersed in conductive solvents evenly, a layer of nanoparticle coating is attached to the surface of the conductive polymer film after the coating and baking processes so that the stability, weather-resistance, and solvent test results of the ink are significantly upgraded, and it can meet the touch market demand fully.

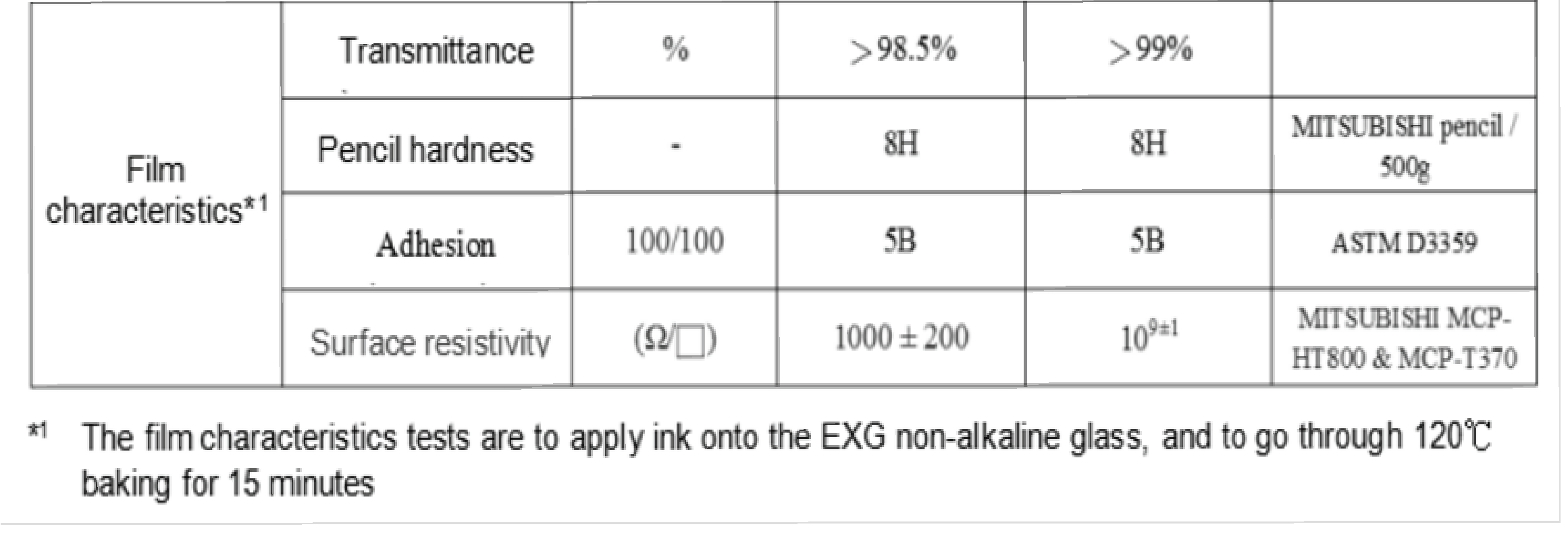

According to the requirements of matches concerning different structures and designs of LCD panels and different inks, Thunder Innovation has developed high hardness conductive/antistatic inks for the LCD panel market. The products can be mainly divided into two types: (1) high hardness and high conductive ink: the surface resistance is of 500-3000 ohm/sq, used in LCD IPS-type electromagnetic shielding applications, the hardness is greater than 6H; (2) high hardness antistatic ink: surface resistance 106-1012ohm/sq, used in LCD in-cell touch surface static electricity dissipation, the hardness is of 6 - 9H.

Conductive polymer ink and anti-static ink

Thunder Innovation’s main operation scope is based on the R&D and production of transparent conductive inks according to different ink demands from the markets. The functions have been improved to meet customer requirements, and different product developments have been made according to different demands.

1.Intelligent dimming film and antistatic coating solution. The intelligent dimming film puts a liquid crystal and polymer mixture between two transparent conductive polymer films. The liquid crystal droplet axis is disorderly arranged in the absence of an electric field effect that makes Mie scattering happen at the interface between light and the liquid crystal droplets and net-shaped polymers, and in turn appears in an opaque state. Under the effect of the electric field, the optical axis of the liquid crystal droplets is arranged in order, so that the light can penetrate the interface between the liquid crystal droplets and the network polymer, so as to show a transparent state. Please refer to figure 4-1.

Figure 4.1 Application of transparent conductive polymer film in intelligent dimming film

Antistatic coating liquid is made of an anti-static material used in PET, PC and other plastic substrates. The end-customers are electronic packaging materials or IC tape and other special specification package material grades with a monthly demand of millions of tons. The resistance values range from 103 - 105ohm/sq to 106 - 108ohm/sq, or even 109 - 1011 ohm/sq according to customer specifications and different requirements.

TCT-LCD panel industry EMI (high resistance) and ITO (500 ~ 1000 ohm/sq): Thunder Innovation has been leading the industry where it took the lead in developing high hardness conductive/antistatic ink which is mainly applied in LCD IPS-type electromagnetic shielding (101 - 104 ohm/sq) and LCD in-cell touch surface static-electricity dissipation (106 - 1012 ohm/sq). The high hardness conductive/antistatic polymer ink is also one of the targeted items of other China, Japan and Korea's big material manufactures’ priorities for developments.

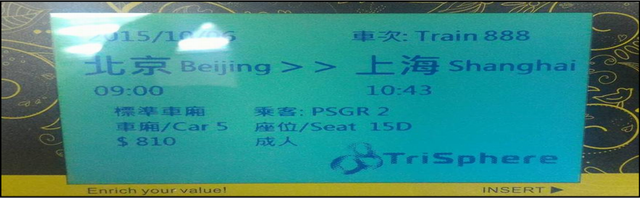

3.Can be re-written to e-paper: Mainly focusing on environmental protection and energy saving for application demands, simply uses "thermal", and is able to have the stored or transferred images written on a soft LCD panel. It has memory function, as shown in Figure 4.2 that simply puts the memory item into the dedicated thermal-writing machine, and you may complete the image clearing and writing process at one time. It has the advantage of repeated uses. At the same time, the thermal writing head size is small with low power consumption, no need for an additional image removal process where the production cost is low and it is easy for mass production.

F

Figure 4.2 Transparent conductive polymer film in the application of rewritable e-paper

4.Projected capacitive touch panels will replace ITO materials. As the projected capacitive touch panel has the advantages of multi-point touch, it has become the first choice for touch solutions of electronic products in recent years. The key transparent conductive film’s surface resistance and transmittance specifications have been upgraded accordingly in addition to the requirements of patterning, in which the key transparent in addition to the requirement of patterning. The surface resistance of conductive polymer ink developed by TriSphere Innovation can reach 150 ohm/sq @ T = 86-87% on the PET substrate. As to the electrode patterning technology, it may reach no etching, low reflection and high contrast effects with de-function etching solution.

There are no products to list in this category.